Lathe, Standard Contact Lens

Maker and role

Robertson Engineering Limited, Manufacturer

Production date

1980

Object detail

Accession number

2018.1.14

Production period

Description

The Robertson Semi-Automatic Lathe. This standard contact lens lathe was manufactured in the UK circa 1980. This type of lathe was extremely robust, cutting a good surface on the plastic to later be polished. This lathe employed a semi-automatic system which enabled the tail stock to cut a lens radius mechanically, preventing hand movement from being transferred onto the cut surface.

The lathe is painted grey metal, composed of several parts. It has a large rectangular metal base. There is a control panel at the front with a line of coloured buttons. There is a clear circular power button on the left, then three rectangular buttons with identification labels above: “ON”, “OFF” and “MAIN SPINDLE”. Underneath these is printed in black “The Robertson Semi-Automatic”. To the right there are six coloured buttons labelled “FINE / COARSE / REPEAT / SET / DAM / AUX / STOP”. Then there is a red stop button and a red manual switch. There are eight labels of different sizes on the front panel of the machine.

On the top of the main unit is a rectangular box with a spindle pointing towards the centre on the left. This is the headstock. It has a metal sign “IMPORTANT / DO NOT MOVE HEADSTOCK / WHILST SPINDLE IS / STATIONARY”. It has a black metal lever and a circular knob on the other end. In front of the headstock is a circular gauge, made by “MITOTOYO”, with a scale from 0 to 100 in increments of 10. Next to this is a metal sign which reads “WARNING / DO NOT OPERATE COLLET / LEVER WHILST SPINDLE IS ROTATING”.

To the right of the spindle is a blue metal upright with an extended arm. There is a black eyepiece which is tilted diagonally. It has an adjustable knob on the right. This is to view the metal circular base below, which holds a metal platform where the contact lens is worked. To the right of the platform is a second gauge, made by “Baty” with a scale from 0 to 100. There is a semi-circular clear plastic ruler around the circular base at the front. On the top edge of the main unit at the top right are two metal signs which read “ADJUST CENTRE” “ADJUST FINE”. There are two metal knobs on either end of the main body of the machine. On the right, “No. 1” is written in permanent marker. The left side has a business card attached with tape, “ELECTRICAL EQUIPMENT CO/ LTD. […]”.

At the back of the machine is the maker’s plate, “DESIGNED AND MANUFACTURED IN U.K. / BY / Robertson Engineering (Thame) Ltd. / SERIAL NO MK4 / 77629 00 / Voltage 240 RPM VAR”. The headstock also has a sign, Headstock label “HEADSTOCK BEARINGS / ARE GREASE LOADED/ NO / FURTHER LUBRICATION SHOULD BE REQUIRED”. There is a lamp which is connected to the back of the machine with a flexible brass-coloured neck. The lamp shade is white metal with a bulb. A cream coloured cord extends from the light fitting and goes inside the unit through a grate at the back. There are two large metal plates on the left and right of the machine. The one on left reads “SPINDLE FORWARD […]” and the right one reads “5 AMP 1 AMP MAIN SWITCH […]” with fuses and a key underneath. There is a grey power cord with 3-pronged plug attached at the bottom right.

Parts 2-4 are held in a small plastic bag attached to main object.

Part 2 - Email correspondence from Nexgen Optical Ltd.

Part 3 - A small rectangular case holding 16 Allen keys and two semi-circular metal plates, one hand-engraved with "8.0" and one engraved with "8.1".

Part 4 - A fuse with a black plastic knob on one end with the word "FUSE" repeated three times.

The lathe is painted grey metal, composed of several parts. It has a large rectangular metal base. There is a control panel at the front with a line of coloured buttons. There is a clear circular power button on the left, then three rectangular buttons with identification labels above: “ON”, “OFF” and “MAIN SPINDLE”. Underneath these is printed in black “The Robertson Semi-Automatic”. To the right there are six coloured buttons labelled “FINE / COARSE / REPEAT / SET / DAM / AUX / STOP”. Then there is a red stop button and a red manual switch. There are eight labels of different sizes on the front panel of the machine.

On the top of the main unit is a rectangular box with a spindle pointing towards the centre on the left. This is the headstock. It has a metal sign “IMPORTANT / DO NOT MOVE HEADSTOCK / WHILST SPINDLE IS / STATIONARY”. It has a black metal lever and a circular knob on the other end. In front of the headstock is a circular gauge, made by “MITOTOYO”, with a scale from 0 to 100 in increments of 10. Next to this is a metal sign which reads “WARNING / DO NOT OPERATE COLLET / LEVER WHILST SPINDLE IS ROTATING”.

To the right of the spindle is a blue metal upright with an extended arm. There is a black eyepiece which is tilted diagonally. It has an adjustable knob on the right. This is to view the metal circular base below, which holds a metal platform where the contact lens is worked. To the right of the platform is a second gauge, made by “Baty” with a scale from 0 to 100. There is a semi-circular clear plastic ruler around the circular base at the front. On the top edge of the main unit at the top right are two metal signs which read “ADJUST CENTRE” “ADJUST FINE”. There are two metal knobs on either end of the main body of the machine. On the right, “No. 1” is written in permanent marker. The left side has a business card attached with tape, “ELECTRICAL EQUIPMENT CO/ LTD. […]”.

At the back of the machine is the maker’s plate, “DESIGNED AND MANUFACTURED IN U.K. / BY / Robertson Engineering (Thame) Ltd. / SERIAL NO MK4 / 77629 00 / Voltage 240 RPM VAR”. The headstock also has a sign, Headstock label “HEADSTOCK BEARINGS / ARE GREASE LOADED/ NO / FURTHER LUBRICATION SHOULD BE REQUIRED”. There is a lamp which is connected to the back of the machine with a flexible brass-coloured neck. The lamp shade is white metal with a bulb. A cream coloured cord extends from the light fitting and goes inside the unit through a grate at the back. There are two large metal plates on the left and right of the machine. The one on left reads “SPINDLE FORWARD […]” and the right one reads “5 AMP 1 AMP MAIN SWITCH […]” with fuses and a key underneath. There is a grey power cord with 3-pronged plug attached at the bottom right.

Parts 2-4 are held in a small plastic bag attached to main object.

Part 2 - Email correspondence from Nexgen Optical Ltd.

Part 3 - A small rectangular case holding 16 Allen keys and two semi-circular metal plates, one hand-engraved with "8.0" and one engraved with "8.1".

Part 4 - A fuse with a black plastic knob on one end with the word "FUSE" repeated three times.

Marks

ELECTRONIC DELAY UNIT MAKES / MOTOR SWITCH INOPERATIVE WHEN / RED LIGHT SHOWS / SWITCH ON GREEN Sticker

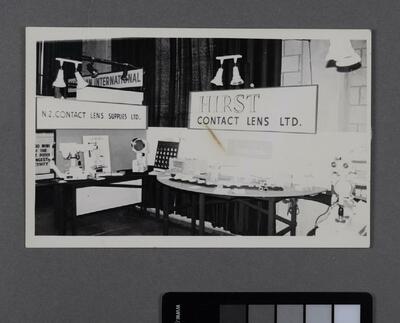

Customer HIRST1 / SERIAL # 122699 / TOOL TYPE / Radius 0.49mm / Cutting Height 6.998mm / Relap date 02/25/04 / RESET […] Sticker

Customer ID / HIRST1 / R0.50mm / Serial 316992 / Radius 0.522mm / Cutting Height 7.324mm / New Jun 22 2011 […] Sticker

WARNING / DISCONNECT SUPPLY / BEFORE REMOVING / THIS PANEL Label

ON / OFF / MAIN SPINDLE / FINE / COARSE / REPEAT / SET / DAM / AUX / STOP Label

The Robertson Semi-Automatic Label

WARNING / DO NOT OPERATE COLLET / LEVER WHILST SPINDLE IS ROTATING Label

IMPORTANT / DO NOT MOVE HEADSTOCK / WHILST SPINDLE IS / STATIONARY Label

MITOTOYO Label

Baty Label

DESIGNED AND MANUFACTURED IN U.K. / BY / Robertson Engineering (Thame) Ltd. / SERIAL NO MK4 / 77629 00 / Voltage 240 RPM VAR Maker's Plate

ADJUST CENTRE ADJUST FINE Label

No. 1 Hand-written

ELECTRICAL EQUIPMENT CO/ LTD. […] Label

HEADSTOCK BEARINGS / ARE GREASE LOADED/ NO / FURTHER LUBRICATION SHOULD BE REQUIRED Label

SPINDLE FORWARD […] 5 AMP 1 AMP MAIN SWITCH […] Label

Nexgen Optical Ltd. [...] Printed

8.0 / 8.1 Engraved

FUSE Printed

Customer HIRST1 / SERIAL # 122699 / TOOL TYPE / Radius 0.49mm / Cutting Height 6.998mm / Relap date 02/25/04 / RESET […] Sticker

Customer ID / HIRST1 / R0.50mm / Serial 316992 / Radius 0.522mm / Cutting Height 7.324mm / New Jun 22 2011 […] Sticker

WARNING / DISCONNECT SUPPLY / BEFORE REMOVING / THIS PANEL Label

ON / OFF / MAIN SPINDLE / FINE / COARSE / REPEAT / SET / DAM / AUX / STOP Label

The Robertson Semi-Automatic Label

WARNING / DO NOT OPERATE COLLET / LEVER WHILST SPINDLE IS ROTATING Label

IMPORTANT / DO NOT MOVE HEADSTOCK / WHILST SPINDLE IS / STATIONARY Label

MITOTOYO Label

Baty Label

DESIGNED AND MANUFACTURED IN U.K. / BY / Robertson Engineering (Thame) Ltd. / SERIAL NO MK4 / 77629 00 / Voltage 240 RPM VAR Maker's Plate

ADJUST CENTRE ADJUST FINE Label

No. 1 Hand-written

ELECTRICAL EQUIPMENT CO/ LTD. […] Label

HEADSTOCK BEARINGS / ARE GREASE LOADED/ NO / FURTHER LUBRICATION SHOULD BE REQUIRED Label

SPINDLE FORWARD […] 5 AMP 1 AMP MAIN SWITCH […] Label

Nexgen Optical Ltd. [...] Printed

8.0 / 8.1 Engraved

FUSE Printed

Media/Materials

Collection

Credit Line

Robertson Engineering Limited. 1980. Lathe, Standard Contact Lens, 2018.1.14. The Museum of Transport and Technology (MOTAT).

Related topics

Public comments

Be the first to comment on this object record.